With an outstanding and experienced technical and after-sales service team, our company provides comprehensive services to nonwoven fabric manufacturers. Our staff proficient in languages such as English, Russian, and Spanish facilitate localized services for customers, reducing the difficulty for on-site staff to operate and use the equipment, thus enhancing work efficiency and user experience. Our customer base currently spans over 40 countries and regions worldwide, including Europe, the Americas, the Middle East, CIS countries, South Asian countries, and African countries. With a deep understanding of local market demands and accumulated experience, we can quickly provide customers with reasonable project application guidance. Experienced engineers provide meticulous installation, commissioning, and operation training guidance for global customers, as well as assisting in R&D.

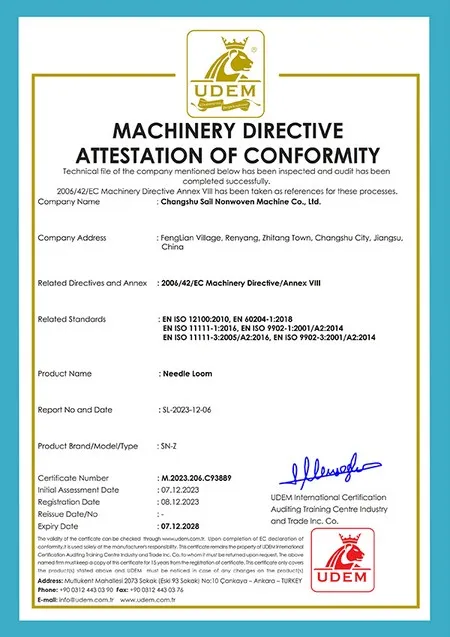

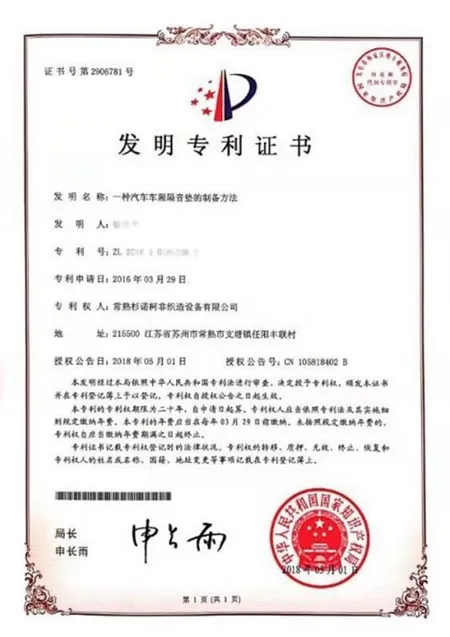

Adhering to the principle of prioritizing quality, we implement strict quality control in every production process and detail. Premium components from renowned suppliers such as Siemens, SNK, and Schneider are carefully selected to ensure stable, safe, and reliable equipment operation. The equipment exported to European and American countries complies with CE, UL, and other certification standards, ensuring reliability. Continuous technological innovation and accumulated experience lead to more rational equipment design, thus reducing maintenance costs for customers and improving production efficiency.

As a well-known manufacturer of nonwoven equipment in China, we are dedicated to providing customers with high-quality and reliable nonwoven equipment. With comprehensive services aimed at effectively reducing your usage, maintenance, and R&D costs, our company offers worry-free and reliable one-stop services, supporting the development and continuous success of every customer.

Factory Tour

We are reliable manufacturer of nonwoven equipment with a self-operated factory, ensuring product quality and controlling delivery time. The factory covers an area of over 8,000 square meters, with a production workshop of 5,000 square meters. We have a team of over 50 engineers and technicians. Our production facilities include CNC machines, cutting machines, paint booths, and testing equipment, etc.