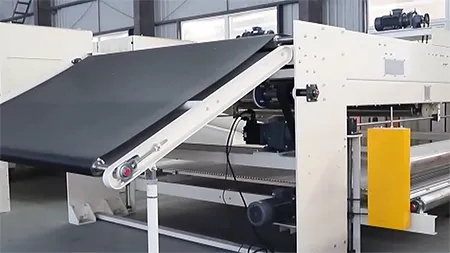

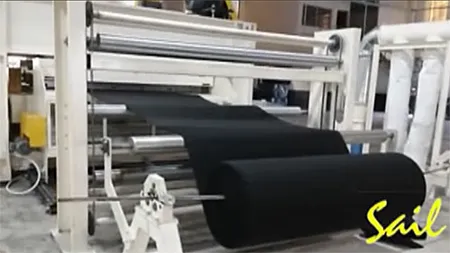

Nonwoven carpet production line

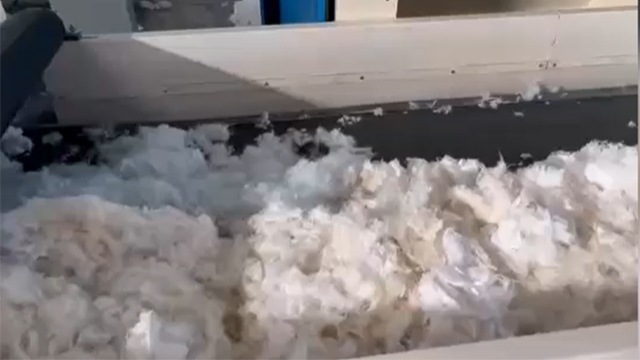

Typically, polyester staple fiber is used as the main raw material for producing nonwoven carpets. The process involves fiber opening, blending, carding, web forming, and needle punching to form the base fabric. Then, various treatments such as velour, jacquard, or striped patterns can be applied, followed by bonding to create nonwoven carpets with different styles or surface patterns.

Learn MoreGet in Touch

Videos

-

Company profile

Company profile

-

Double cylinder carding machine

Double cylinder carding machine

-

Medium speed cross lapper

Medium speed cross lapper

-

Vertical lapper

Vertical lapper

-

High speed needle punching machine (needle loom)

High speed needle punching machine (needle loom)

-

Double board needle punching machine

Double board needle punching machine

-

Velour needle loom

Velour needle loom

-

Nonwoven carpet production line

Nonwoven carpet production line

-

Automotive insulation felt production line

Automotive insulation felt production line

-

Synthetic leather substrate production line

Synthetic leather substrate production line

-

Cleaning cloth production line

Cleaning cloth production line

-

Spray bonded wadding production line

Spray bonded wadding production line

-

Filter felt production line

Filter felt production line

-

Thermal bonded wadding production line

Thermal bonded wadding production line

Nonwoven Wipes Production Line

Nonwoven Wipes Production Line Geotextile Production Line

Geotextile Production Line Shoe Material Production Line

Shoe Material Production Line Nonwoven Felt Production Line

Nonwoven Felt Production Line